Industry best-practices harnessed to improve Maintenance & Reliability index

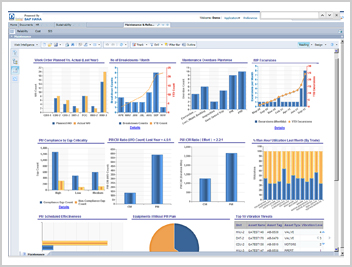

Rolta OneView™ has prebuilt maintenance and reliability analytics based on the Oil & Gas industry’s best operating practices. Harnessing these insights greatly enhances the Maintenance and Reliability Index of an organization. These insights are built by aggregating and correlating data across ERP, condition monitoring systems, vibration monitoring systems, MOC systems, inspection management systems, risk & reliability management systems and engineering systems. Historical analytics and equipment failure predictions enable the optimal planning of maintenance schedules.

Rolta OneView™ Maintenance & Reliability Insights include analytics for critical business scenarios such as maintenance planning & scheduling, capacity planning, disaster recovery planning, spare parts management, inventory tracking, risk & reliability management, corrective repair, PM compliance, well workovers, shutdown planning and annualized maintenance cost.

These prebuilt maintenance & reliability analytics help organizations to

- Eliminate worst actors

- Effectively manage work-order backlogs

- Effectively plan resources

- Utilize workforce better

- Minimize shutdown & turnaround duration

- Improve preventive maintenance compliance

- Improve asset integrity

- Ensure spare parts availability for critical equipment

- Improve safety